Here is a sample that showcases why we are one of the world’s leading academic writing firms. This assignment was created by one of our expert academic writers and demonstrated the highest academic quality. Place your order today to achieve academic greatness.

This research investigates the impact of project production management and advanced analytics on improving project delivery in the oil and gas industry. Project delivery system for the oil and gas industry improves the supply chain management of the oil and gas firms. Inventory management enables the companies to avoid losses due to cost and time consumption increases.

Big data and analytics improve the overall efficiency and connectivity within the oil and gas enterprises by reducing the cost and overall time required for operations. A positivism philosophy was used for this investigation along with an inductive approach due to the absence of a hypothesis.

An exploratory research design was chosen to incorporate new information regarding the research topic. The research was conducted by following the qualitative strategy as qualitative information had been collected from an interview conducted with the managers of Tengizchevroil in Kazakhstan.

Production management is found to be important for ensuring timely project delivery for the oil and gas companies. Big data, analytics, and digital technologies are important for overcoming the complexities bind using digital transformation in the sector and maximizing the health and safety of the workers.

Increasing the efficiency of oil production and higher conversion rates during refining leads to greater efficiency and reduced waste and carbon emissions. The research concluded that there has been a positive effect on the oil and gas industry’s operational activities and production process with the incorporation of project production management and data analytics. However, it has been recommended to incorporate mixed-method analysis to increase the quality of this research and have an increased in-depth analysis relating to the topic of this study.

The oil and gas industry incorporates the global procedures of exploration and extraction of crude oil followed by its transportation through the oil tankers and pipelines followed by its marketing of the petroleum products. Project production management (PPM) incorporates applying the principles of operations management to ensure the timely delivery of capital projects (Baiden & Price, 2011).

This framework enables the project managers to perceive the projects as a production system for analysing the transformation of the inputs including the raw materials and the information and labour into the outputs like goods and services. Project delivery includes utilising the overall project management system for the design and finance of the project for ensuring its seamless operations and maintenance (Kerzner & Kerzner, 2017).

Analytics is the process of analysing data using advanced software powered with autonomous or semi-autonomous methods with AI-based sophisticated tools (Nicholas & Steyn, 2017). The topic of this research is to analyse the impact of project production management and advanced analytics on the improvement of the delivery of projects in the oil and gas industry.

This chapter of the research incorporates the background and research problem followed by the justification of the selection of the research topic in the research rationale. The aims and objectives to be explored in the investigation are also incorporated in this section and an outline of the chapters have also been provided.

Multiple production sites are used for extracting crude oil through drilling. The production of oil and gas in valves extraction of the hydrocarbons and separating the mixture of liquid gas and hydrocarbons along with solids and water from the non-saleable constituents. This is followed by the sales of liquid hydrocarbons and gas after refining.

Oil and gas are the major industries in the energy market having the most influential role in the global economy due to being the primary sources of well for transportation and energy production (EWG, 2021). The process of production of oil and gas along with its subsequent refining and distribution is highly complex and requires state of the art technology along with a high amount of financial capital.

However, the profits of the industry have reduced over the past decades due to lower revenues and cash flows. This is due to the variation of demands in the market along with the entry of numerous operators. The environmental concerns regarding the extraction of oil and gas leading to carbon emissions and leakage of toxic substances into the soil and sources of drinking water have altered the perspectives of consumers towards renewable and alternate sources.

Fuel oil and petrol are the largest volume products generated in the oil and gas industry and petroleum is also used as a raw material for multiple chemical products and pharmaceuticals (Yeldan, 2019). Crude oil is of extreme monetary value due to its requirement for transportation and industrial purposes and is also known as Black gold.

The oil and gas industry operations are divided based on upstream, midstream and downstream activities. The upstream activities include exploration and extraction of crude oil whereas the midstream operations include the transportation and storage activities. The downstream operations include refining the crude oil into petrol and the other end products.

Project management and delivery are vital in the oil and gas industry as it comprises complex and hazardous operations what millions of dollars (Nicholas & Steyn, 2017). The efficiency of project delivery in the oil and gas industry is poor compared to other industries like retail and traditional manufacturing.

Advanced analytics enables businesses to utilise their store data and benefit from well-organised business intelligence. This is suitable for decision making concerning the future demand and supply along with market conditions in the oil and gas industry leading to the scope for better utilization of the available resources, labour and infrastructure to reduce costs.

The oil and gas companies face difficulties in project management leading to the failure to deliver consistent quality to the clients along with delays and budget overruns. The delays and quality issues mostly arise due to the inefficiencies along the supply chain and operations leading to the life of coordination and communication among the team members.

The supply chain in the oil and gas industry is highly complex and volatile leading to the involvement of numerous materials and a high inventory rate. This condition challenges the project delivery and output in the oil and gas industry. There is also an ongoing issue of environmental impact, sustainability and safety of the personnel operating across the oil and gas projects.

The low-efficiency rate and project delivery issues stem mostly from the cost-efficiency issues and idle machines and labour. The poor working conditions along with safety hazards result in management difficulties and causes a delay in the project delivery resulting in losses of millions of pounds every year. The selection of the appropriate PM methods for project delivery along with appropriate analytical tools is essential for timely completion of the project and achieving efficiencies to retail maximum profits (Cullinane & Wilson, 2017).

The research topic is rational as it evaluates the project delivery limitations in the oil and gas industry. There is a literary gap in research regarding the solutions of the project delivery issues in the petroleum sector; hence, this research presents a potential solution to the challenge. This is done by identifying the potential role of project production management and analytics for improving operational efficiencies using advanced tools. The research eliminates the gap in knowledge about the methods of improving project delivery in oil and gas. The research topic also benefits the project managers to use the latest digital technologies to improve efficiencies while creating scope for higher profitmaking for the oil and gas firms.

The research aims to investigate the impact of project production management and advanced analytics on improving project delivery in the oil and gas industry.

The research objectives are:

The research questions are:

The research has a total of five chapters that are as follows:

This chapter introduces the resource topic and provides the background information, aims and objectives.

This chapter incorporates the past studies and literature associated with the research topic. Also, the relevant theories and concepts associated with project production management and project delivery have been presented.

This chapter of the study presents details about the research method that has been chosen for data collection and analysis.

This chapter presents the results based on the data that had been collected and its subsequent analysis.

This chapter of the research controls the findings and provides recommendations to the companies and their management.

Orders completed by our expert writers are

The oil and gas industry includes projects involving the extraction of crude oil and its transportation and refining for producing petrol and other industrial chemicals. The industry had witnessed its profits decline over the past decade along with going through financial instability due to a reduction in revenues and cash flows.

The industries in fossil fuels have lost billions due to a fall in stock prices and increasing bankruptcies. This is due to the rising popularity of renewable power and electric vehicles. Enhancement in the quality and efficiency of project delivery is an available option for the oil and gas operators to reduce their overhead costs and ensure the increase in output through minimum investment.

Managing the projects in the industry includes the endeavours of reducing the cost and enhancement of the process efficiencies along with the management of timetables (Cullinane & Wilson, 2017). The inefficiency of the existing machines and infrastructure used for project management leads to inefficient output as more lead time is required despite the unreasonable production schedule.

The integration of advanced technologies like the internet of things and analytics creates the scenario of efficient project production management leading to the minimization of waste and optimum utilisation of the available resources for achieving the deliverables in time.

An improvement in the capital project delivery mechanisms presents a scope of growth to the oil and gas operators for maintaining the timetables and improving continuously. The use of PPM along with advanced analytics and digitisation presents an opportunity to reduce lead times and overcome challenges.

The literature review presents the past literature of authors regarding the research topic. This includes the concepts of PPM, project delivery and advanced analytics. A literature search strategy used in the study to identify relevant academic materials from online databases is like Google scholar, ResearchGate and Science Direct.

This had been coupled with the use of keywords for searching relevant journals and academic materials about the research topic. The topics searched included project production management, advanced analytics, supply chain, operations management, project delivery, oil and gas industry etc.

Project production management helps in the management of operational activities and helps in the delivery of different capital goods or products within the oil and gas industry. Furthermore, the PPM “(Project Production Management)” is formed on the framework of systematic project view with different inputs like labour, raw materials, plant & machinery, and other operational information (Lin and Golparvar-Fard, 2021).

In addition to that, the project production management framework also undertakes to analyse and calculate the output variables like services and goods from the aforementioned inputs. According to the words of Jacobs (2017), the oil and gas industry across the world has emerged to face some situational challenges like the incorporation of big data available within the sector with no proper information available. Therefore, the oil and gas industry has emerged to incorporate different performance improvement factors like sensor technologies and proper availability in the broadband network for the management of big data.

Knowledge management system within the oil and gas industry has also emerged to standardise and implement technological and people management to be challenging in nature. Furthermore, a proper knowledge-based management system can be implemented by incorporating key stakeholders within the core areas and including different assets (Santoro et al. 2018).

This helps in understanding and developing a knowledge-based management system within the oil and gas industry through the incorporation of centralised knowledge and flexible implementation of big data. On the contrary, Park et al. (2020) state that a knowledge-based management system refers to the integration of information databases within project data. Furthermore, the study found that knowledge-based management systems might also require human activities within their operations due to less automated processes.

The oil and gas industry within developed countries like the United Kingdom has also emerged to face some serious difficulties related to efficiency levels for inadequate supply of data from knowledge management and delivery of projects (Ji et al. 2018).

Moreover, 65000 jobs were reported to be lost within the oil and gas industry of the UK due to a reduction in overall levels of activity and an increased threat to sustainability for a major fall in the prices of commodities (BBC, 2015). Furthermore, the oil and gas industry has improved within its operational management through active involvement from individual companies to ensure growth within the concerned sector.

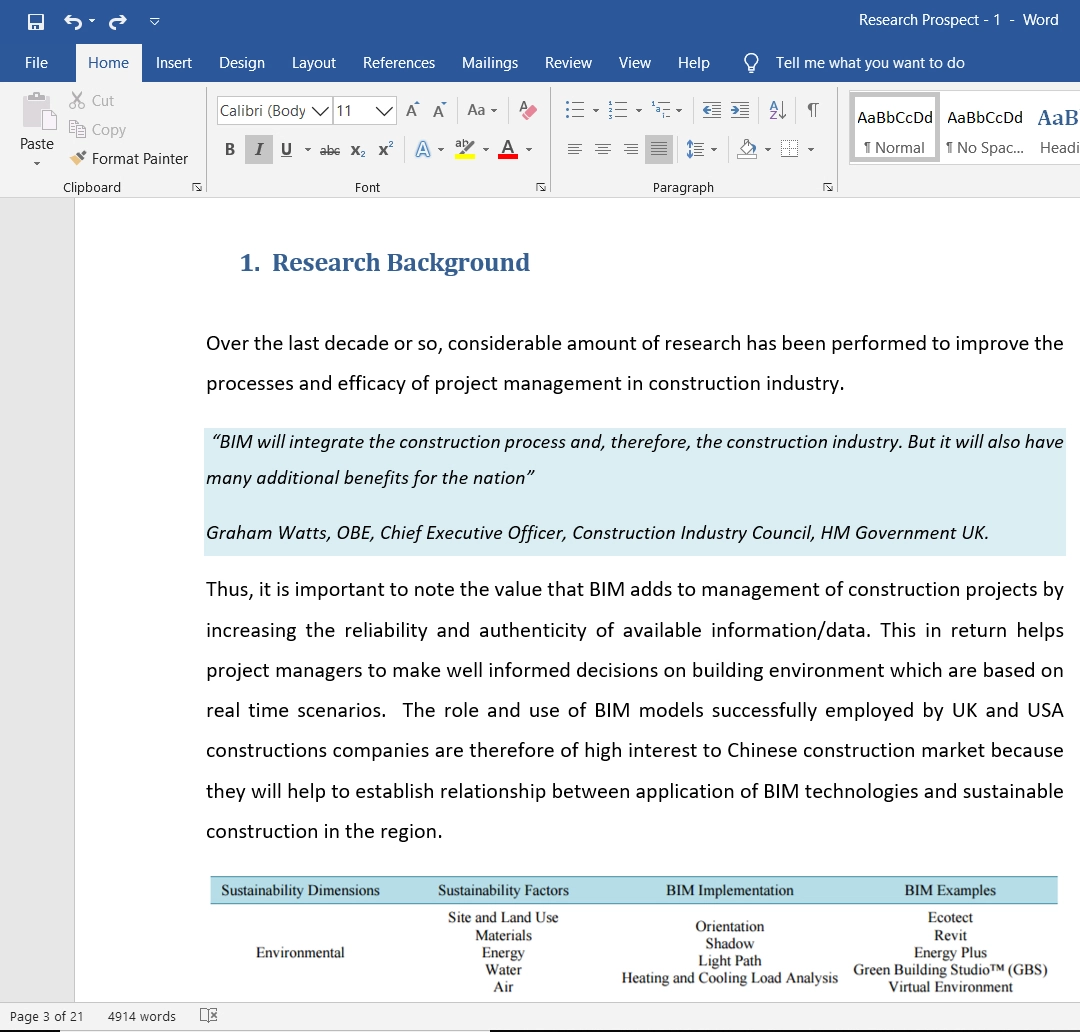

Figure 1: Employment reduction in the oil and gas industry

(Source: Statista, 2020)

The figure depicted above highlights the global change in the reduction of employment within the oil and gas industry. Upon closer analysis, 2014-2016 saw a decline in overall employment by 42% on average which the COVID-19 pandemic has further impacted in recent times. A sharp decline in the consumer demand for petroleum products further increased the production processes, which will directly impact the employment generation of the global oil and gas industry (Statista, 2020).

Moreover, the shale sector of the concerned industry was among the worst-hit sections with an average decline in the employment rates. Furthermore, there has been a record of a sound 30% reduction in the overall employment rates in recent months after the impact of the 2016 oil crisis.

Operations in the oil and gas industry have further been subdivided into two parts: upstream and downstream production of oil and gas. According to Attia et al. (2019), upstream production in the oil and gas industry emerged from the identification, extraction, and further production of raw materials for business in the petroleum industry.

On the contrary, downstream production from the oil and gas companies is mostly consumer-oriented, with ends closer to end customers. As opined by Attia et al. (2019), upstream production for oil and gases focuses on the identification of deposits and recovery of raw materials.

Therefore, the current situation can be further analysed through operations management’s business process redesigning theory. As per the words of Chang et al. (2019), business process redesigning refers to the structural modification of a business process through the incorporation of improvements in cost, service, and quality. Therefore, operational management may be improved through a singular structured method by further modifying the business designing process in the oil and gas industry.

Figure 2: Business process reengineering framework

(Source: Influenced from Chang et al. 2019)

The figure depicted above highlights the business process reengineering framework that can be implemented within the global oil and gas industry for effective operations and supply chain management. As opined by Dachyar and Sanjiwo (2018), business redesigning in the oil and gas industry may be achieved through the initiation of clubbing the operational process into a singular method and following the same through efficient monitoring processes. Furthermore, this shall help the oil and gas sector reduce its major losses and employment along with the losses affecting inefficient outputs with longer lead times.

Management of projects refers to the decision-making processes made during the process of data mining and techniques of machine learning. The global oil and gas industry emerge to hold huge data for the production processes and effective and efficient management of the same is required through proper implementation of advanced analytical technologies in supply chain management.

As per the words of Gardas et al. (2019), implementing sustainable supply chain management within the oil and gas industry shall further help address the sector’s social and environmental concerns. Moreover, the study also highlights the influence of operational and business performance on sustainable supply chain management practices.

On the contrary, the words of Ahmad et al. (2017) states that sustainability within the oil and gas industry is affected on a global level through external factors like pressure from social issues, corruption, and poor infrastructure within the oil and gas firms. Therefore, the aforementioned factors are found to significantly impact the sustainable performance supply chain management system within the oil and gas global industry.

As per Popkova et al. (2019), Analytics allows the characterization of the available organisation of data with the use of a centralised data management system. This enables the organisational managers and decision-makers to observe daily production values and view failure analysis to enhance future operational procedures.

The organisations are able to benefit by accessing rich insights from large data sets regarding the procurement and processing of oil and natural gas leading to more profitability in the future. The oil companies forecasting the potential information regarding the availability of soil and its perceived quality remains capable of minimising the operational cost and ensuring transparency in the evaluation of the data set.

Data analytics helps to characterize and analyse the seismic data along with improving the simulation and characterization of the reservoirs (Ahmad et al. 2017). This leads to a reduction in the time of drilling and increases the health and safety of the workers. Data analytics helps optimise the production farms and improve the petrochemical asset management activities. The shipping and transportation efficiency of the oil and gas companies and the overall supply chain are also improving due to data analytics.

However, using data analytics within the concerned industry helps in effectively utilising and implementing resources, which further helps to make better forecasts of costs and revenues for the oil and gas firms. The incorporation of big data and unrelated data within the industry can be effectively analysed through data analytics to ascertain projections and early warning signs for important projects (Nadikattu, 2020).

On the contrary, words of Lytras et al. (2017) state that data analytics undertakes various analytical methodologies like statistical or operational and lean six sigma models. Therefore, the incorporation of project analytics further helps in the improvement of project success rates through efficient abilities for strategic decisions through the incorporation of big data from the oil and gas industry.

Inventory management system refers to the processor system of wireless networks through effective management via computational intelligence of predictive analytics in “Industrial Internet of Things” (Jayaram, 2017). Furthermore, the IIoT is found to improve the process of data collection from various sensors and machines of the oil and gas industry that shall further aid in improving the demand for the same. Different inventories present within industries are mainly raw materials that are mainly extracted by the enterprises of the oil and gas industry. In addition to that, the other factors include work in progress and finished goods within the production process.

Figure 2: Inventory management model in global firms

(Source: Influenced by Jayaram, 2017)

The inventory management model is found to be depicted in the figure above for the major global firms. Upon closer analysis, the oil and gas industry is global in nature has the capability of accessing the inventory storage levels for the manufacturing and storing of liquid petroleum.

Additionally, oil and gas firms across the world can efficiently use the inventory management model to identify the loss through leakage or other natural or man-made factors through the incorporation of the Industrial Internet of Things (Popkova et al. 2019).

Moreover, the words of Ijiga et al. (2020) states that IIoT can be implemented through the incorporation of emergent configuration that helps in improving efficiency levels of IoT systems in improving customer satisfaction levels. Thus, the study was also able to highlight the anthropogenic oil or gas spillages from the production processes by effective management of exploration processes during the collection of raw materials.

Internet of Things is also found to improve the efficiency and connectivity levels in enterprises and industries by saving vital time and cost of the firms (Nord et al. 2019). In addition to that, lean manufacturing processes can be hereby mentioned to be implemented by the Industrial Internet of Things that significantly minimize the wastage of materials and on the other hand, increase the productivity levels of the businesses (Popkova et al. 2019). Therefore, it can be stated that the incorporation of IIoT within the businesses significantly improves the production process management.

Figure 3: IIoT quality management for global enterprises

(Source: Influenced by Jayaram, 2017)

The oil and gas industry across the globe has emerged to be suffering from various operational and inventory management processes that can be further improved through the incorporation of IIoT. The figure depicted above highlights the different roles undertaken by IIoT through the “inventory management model” within the global enterprises of the oil and gas industry.

According to the words of Wanasinghe et al. (2020), a drastic decline in oil prices within the oil and gas industry has forced the industry to switch towards modern technological advancements to improve the operational and efficiency of assets and minimising the health and safety risks and environmental risks which further gives rise to the overall portfolio of the firms.

Therefore, enabling the advantage of real-time data collection from the oil and gas companies also helps in achieving the concerned objectives (Mahmood, 2019). Furthermore, the need for improvement in quality or performance management is highlighted through the pace of adopting IoT in upstream, downstream, and midstream operations.

Collected data is easily segregated through the patterns built from the large data for identification of relevant themes and variables through the incorporation of IoT. As opined by Temer and Pehl (2017), smart monitoring techniques are applied by IoT for maintenance and identification of spaces that require quality management ranging from inventories and work in progress.

Therefore, the study also highlights the major use of IoT in improving the inventory process quality management within oil and gas firms by acting as a catalyst through the collection of the analysed data that is used for identification of improvement in qualities (Jayaram, 2017).

Thus, the major factors being analysed and acted upon by the Internet of Things within the oil and gas industry are lower readiness in technological advancements, cyber-attacks within the firms’ huge database, or unavailability of labour and communication channels (Wanasinghe et al. 2020). Moreover, the aforementioned factors are mitigated by the incorporation of IoT within the oil and gas industry across the world.

Impact of project production management and advanced analytics on improving project delivery in the oil and gas industry

The oil and gas industry were found to significantly suffer in recent times due to the reduction in overall demand from consumers globally due to the impact of the Covid-19 pandemic.

Furthermore, the drastic reduction in demand has called for the incorporation of advanced analytical tools for the improvement in project delivery systems within the concerned industry. As per the words of Walker (2015), production management refers to the management of operations within an organisation for effective planning and control of industrial processes to ensure smooth movement of resources at required levels.

Therefore, the requirement to introduce production management within the oil and gas industry has emerged to be vital due to various challenges like complex operational costs and inefficient optimisation of employees. As opined by Baryannis et al. (2019), artificial intelligence has been found to improve the operational management system within the oil and gas industry by analysing the valuation of specific reservoirs with petroleum, understanding the geological origin of a particular area with customised drilling, and planning.

Furthermore, the study also found to assess the risk levels of the individual wells for mining through the incorporation of big data analytics and ascertain the lifetime for the production of the same wells. In support of the above context, Baryannis et al. (2019) stated incorporation of artificial intelligence also helps in the optimisation of trading and hedging different strategies and also forecasts the long-term input for commodities within the oil and gas industry. Moreover, the midstream and refining process within the industry is also helped by AI technology to improve labour productivity levels and wastage of time.

In addition to that, supply chain management has also emerged to be a negative factor in the oil and gas industry due to the disasters occurring at oil rigs and proving to be negative business performances for the firms. As per the words of Khoramfar et al. (2017), the oil and gas industry may further improve their capital project performances through the power of advanced analytical technologies and implementation of PPM that provides additional control over the project production process.

Therefore, operational management within the oil and gas firms may be further improved by minimising the work in progress and maximising the overall output levels. As opined by Mohammadpoor and Torabi (2020), big data analytics has been essential in helping the seismic and “microseismic data” for improving reservoir characteristics and reduction in drilling time with increased safety measures.

Moreover, the application of big data analytics within the oil and gas industry has further helped in occupational safety measures within the concerned firms through improvement in transportation and shipping, and management of petrochemical management of assets.

Although big data analytics has emerged to be of significant importance within the oil and gas industry, challenges like reduced awareness levels among the firms regarding the software and lack of adequate support from businesses have faced difficulties in understanding the complexity of the challenges.

According to the words of Alkhaldi et al. (2017), human safety has emerged to be of significant importance for O&G companies due to the harmful emissions that negatively impact the workers. However, implementation of big data and predictive analytics are found to help the concerned firms through the identification of oil and gas sources through software development reducing risky endeavours and hazardous operations.

On the contrary, the words of Flichy and Baudoin (2018) states that big data analytics helps in improving the security levels keeping a constant track of operational measures occurring within the oil rigs that further aids in quicker identification of mishaps occurring within the mines.

Therefore, big data analytics also helps the oil and gas companies to increase security levels for the consumers. As per the words of Priyanka et al. (2020), big data analytics helps in the identification of health equipment for the workers through the incorporation of huge data from the sensors. Additionally, it also helps the firms to identify the defective machinery responsible for decreasing the overall efficiency of the business for further removal or replacement.

Big data analytics is also found to increase the discovery of newer oil mines for the companies through the inclusion of “ad-hoc” software and deep analytics. Furthermore, big data analytics is also found to improve data organisation and management of larger data for further analysis through extraction, cleansing, and integration processes (Eissa, 2020).

Moreover, Big data is generally stored across the servers of industry standards and clusters of software development. On the contrary, the words of Cappa et al. (2021) states that big data mainly consists of three types of dimensions, namely variety, volume, and velocity that further helps in the analysis process.

Furthermore, volume stands for the total amount of data considered by the analytical software during the time of analysis, whereas variety refers to different types of data collected. Thus, the words of Nguyen et al. (2020) stated the oil and gas industry has also been helped significantly by big data analytics as it incorporates huge amounts of unrestricted data into proper segregation processes.

Big data has also emerged to have a positive impact on the upstream oil and gas industry through the acquisitions of improvement in seismic devices, counting of channels, maintenance of carbon capture, or monitoring of fluid levels through geophones (Mohammadpoor and Torabi, 2020).

In addition to that, the introduction of STEM tools within the oil and gas industry has brought a sustainable change in the development of business through a collection of data sets of the oil companies. Moreover, the understanding of patterns from large datasets through the implementation of stem tools has been highlighted below,

Figure 4: Relationship between STEM tools and perception of patterns in big data

(Source: Influenced by Mohammadtapor and Torabi, 2020)

The above figure highlights the relationship between the STEM tools and the identification of patterns within big data analytics. Moreover, the figure also suggests a limited amount of data incorporation within the framework shall provide vague results which are harmful to the oil and gas companies (Mohammadtapor and Torabi, 2020). Therefore, the necessity of incorporating big data for O&G companies has been proved to be essential through the above framework.

Adoption of agile within the front and end of different projects has also been proved as important for the O&G companies as it is widely used for 20 years. As per the words of Hoda et al. (2018), agile technology is a fast and cross-functional section for the decision making procedure of the companies in the oil and gas industry.

Furthermore, agile helps in the formation of small teams for effective management and facilitation in smooth decision-making procedures. In addition to that, the aforementioned approach helps the industry to reduce the challenge of wastage in additional time as it emerged to be fast with minimum chances of error.

The current research highlights the positive impacts of project production management and advanced analytics through the incorporation of big data analytics has helped the oil and gas industry to improve their operational and production management of the firms.

However, the current study has failed to incorporate the environmental impacts the oil and gas industry has on the environment. Due to the extensive usage of fossil fuels having negatively impacted the environmental factors, the future study has the scope to include the aforementioned factor within the research study.

The current section highlights the data collected from existing literature bases in project production management and its positive and negative impact on operations. In addition to that, the study has also emerged to find significant changes and negative impacts over the oil and gas industry for a reduction in the employment rates of the workers.

Furthermore, the recommendation for improving the industry through a “business process reengineering framework” has helped it to recover from the majority of losses faced through the redesigning and reconstruction of the existing business framework.

Moreover, the project delivery system for the oil and gas industry was also found to improve from the evidence of existing literature as it highlighted the implementation of advanced analytical technologies within the supply chain management system. Furthermore, the inventory management model has been incorporated within the study to understand the major losses and challenges faced by the companies due to increases in cost and time consumption. The incorporation of big data analytics improved the overall efficiency and connectivity within the enterprises by reducing the cost and overall time required for operations.

Supply chain management within the oil and gas companies has emerged to suffer significantly due to the negative impacts of the Covid-19 pandemic on the efficient supply of raw materials and labour. However, implementation of project production management has also been found to minimise the work in progress levels and maximise the total output levels within O&G companies.

The oil and gas industry is one of the most important sectors across the globe and is responsible for generating a massive percentage of the global GDP. The Covid-19 pandemic in 2020 had resulted in severe losses for the oil and gas industry due to a complete halt in consumerism as the worldwide governments imposed a lockdown with restricted transport and mobility.

This caused massive turbulence in the supply chain and operations of the oil and gas companies leading to losses worth millions of dollars and thousands of employees being made redundant. However, the global oil and gas market is expected to reach a valuation of $5780 by the end of 2021 with a CAGR of 25.5% as a sign of market recovery.

The oil and gas companies have initiated the process of digitalization of the businesses to optimise and streamline the traditional production and supply chain processes and reduce the timetables. The use of advanced analytics and project production management has also found its way across the oil and gas companies for the establishment of discrete production systems for separate management of the activities and the elimination of variability in performance.

This chapter presents the methodologies influencing the research methods of collection and analysis of the data in this investigation for identifying the ways in which project delivery across the oil and gas companies can be improved. The oil and gas industry of Kazakhstan has been focused upon in this investigation for understanding the scope of application of the modern technologies and processes including analytics for optimisation of the operations and supply chain for improving the rate of delivery. The research methods were based on the Research Onion suggested by Saunders (2011). This led to the selection of the philosophical underpinnings and the approach undertaken by the investigator.

Figure 1: Research Onion. Source: (Saunders, 2011).

Identification of the purpose of research is essential for ensuring its comprehensive completion within the stipulated time frame . The foremost purpose of any research is to accomplish its aims and objectives along with providing answers to the research questions.

The research purpose answers the question concerning the reason due to which the investigation is being conducted relating to the research problem (Williams, 2007). The purpose of this research is to critically analyse the area of project management concerning the project delivery in the oil and gas industry of Kazakhstan. The research purpose includes the identification of the ways in which advanced analytics and other methods including project production management can be applied for the enhancement of project delivery.

The accomplishment of the research objectives had led the investigator to provide solutions to the research problem including delay and losses in the oil and gas industry along with the process inefficiencies.

The research philosophy represents the thought process and perspectives of the investigator regarding the choice of selection of the methods for data gathering and synthesis. The process of data collection in research includes the procedures of collecting and gathering relevant information matching with the research topic and utilising the same thorough analysis and evaluation .

The research methodology selected by the investigator influences the development of information along with the formulation of the research conventions that are followed throughout. The research onion is classified into four different categories of research philosophies that include positivism, interpretivism, pragmatism and realism.

The positivism research philosophy is established on the notion of the existing reality being permanent and anointed and hence being easily identifiable based on the pursuit of the research objectives . This philosophy has been associated with the creation and development of fresh perceptions regarding the research topic.

The interpretivism research philosophy is associated with the evaluation of the individual elements in the research question. This philosophy enables the investigator to represent the existing facts along with utilising multiple perspectives for data interpretation. The realism research philosophy integrates the attributes of positivism and interpretivism . The pragmatism research philosophy provides a free hand to the investigator to incorporate any methods required and available for the achievement of the research aims and objectives.

The research is aligned with positivism philosophy. This has led to the integration of factual data and knowledge about the oil and gas industry of Kazakhstan and provided details about the condition of project delivery in the country having the 12th largest reserves in the world.

The choice of positivism philosophy enabled the investigator to become exposed to the external worldviews of first and participants for enhancing the quality and authenticity of the research findings (Williams, 2007). The positivism worldview enabled the researcher to incorporate a scientific logic and meaningful explanation of the phenomenon in the study (McNeill, 2006).

The research approach of an investigation is of two categories based on the research onion are inductive and deductive . The choice of the research approach in research is essential for determining its progress pattern and helping the investigator in ensuring seamless progress of accomplishing the research objectives.

The research approach is crucial for establishing a predictable pattern of progress in the investigation. The research approach enables the investigator to synthesise the collected data for the generation of fresh perspectives regarding the research topic . This approach leads to the identification of the elements in the research topic and their linkage in addition to delivering an account of the absent concepts and required recommendations.

The deductive research approach is generally undertaken during the presence of predefined relationships among the research variables and the inclusion of a hypothesis that requires to be tested. This is based on the understanding and acknowledgement of the interrelationship between the dependent and independent variables in the research.

This research was conducted with the inductive approach. This approach has been undertaken due to the absence of existing theory or hypothesis among the elements in the research topic (McNeill, 2006). The inductive approach has facilitated the creation of new theory and facilitated the establishment of linkage among the elements in the research topic. This included project production management, advanced analytics and project delivery concerning the oil and gas industry.

Research design represents a general framework for the overall investigation and provides an important assistant to the investigator for explaining the elements in the research topic . Research design is used to deliver appropriate solutions to the research problem along with helping to accomplish the desired outcomes within the due time frame.

The research onion classifies the research design into the categories of descriptive, explanatory and exploratory research. The descriptive research design enables the investigator to refer to various information sources for the extraction of information regarding the research topic.

This helps in the representation of the research problem and its potential solutions with their reference to complete information about the subject. The exploratory research design enables the investigator to consider the existing sources of evidence for exploring the elements of the research topic by conducting a thorough investigation (Crowther and Lancaster, 2012). The exploratory research design provides the scope of establishing a deeper understanding regarding the research question with the reference of new information sources.

This research was conducted by following the exploratory design. This has been done to successfully incorporate new information regarding project production management, advanced analytics and project delivery. The choice of the exploratory design is justified as there is a lack of evidence regarding PPM and advanced analytics in the oil and gas industry.

The exploratory research design selected in this investigation has created the scope for unearthing thing new information regarding the potential benefits of project production management and data analytics on the deliveries in the oil and gas companies. This has created the scope for expanding the horizon of the research by integrating the other disruptive technologies and tools that are available for potential use in the oil and gas industry.

The research strategy represents the overall procedures that are required to conduct an investigation including the selection of methodologies and methods . The research strategy used in this investigation is qualitative. This represents the use of qualitative data in this investigation that has been gathered from both primary and secondary sources.

This has been followed by an evaluation of the primary data using suitable methods that are discussed in the subsequent sections. The quality strategy is selected in this research is justified as it creates the scope for incorporating human experience along with using the experience of the researcher.

In this research, data collection regarding project production management was collected for the identification of the parameters of efficiency in project delivery and management by consulting primary and secondary data sources . The required data regarding the challenges of project delivery and production management in the oil and gas industry of Kazakhstan has been collected from the data sources.

The data collection also included essential details about the contribution and probable benefits of advanced analytics in the improvement of project delivery in the industry. Additional details regarding the significance of project production management in the oil and gas industry for improving delivery efficiency has also been gathered from the primary and secondary sources.

The primary data has been collected from qualitative sources to ensure proper and in-depth knowledge about the research questions. Interview with 8 managers of Tengizchevroil (Chevron) was conducted for gaining knowledge about their operations in Kazakhstan and the status of project management and delivery. Kazakhstan has rich reserves of petroleum and it is the largest landlocked nation in the world.

The managers were asked open-ended questions in the interview that was conducted through video conferencing due to constraints of physical travel, limited time and budget. This had enabled the identification of the issues that are presently plaguing the company. The interviews lasted 10 minutes each for the individual interviewees. The interviews were recorded through skype for referring to the same during analysis.

Some secondary sources had also been used in the research for data collection that included the different academic books, journals articles and periodicals. The literature search was done across research databases like Google Scholar, Science Direct and Research Gate.

The keywords were: project production management, production, project management, advanced analytics, project delivery, oil and gas industry, oil and gas, improving project delivery. More than 100 sources were identified applying the keywords singly and in combination. The inclusion criteria included the sources being published on and after 2012.

The secondary sources were used concerning the availability of information about project delivery in the oil and gas industry. The data gathering had enabled the researcher to identify the factors that affect project delivery and also uncover the methods that are presently being used across the sector.

Data analysis is an important component of this and any investigation as it deals with the process of written examination and altering for the identification of useful information (Bello & Kostova, 2012). The qualitative data collected in this investigation from the interview with the managers of Tengizchevroil and the secondary information sources have been evaluated using thematic analysis.

The interviews were transcribed by listening to the recording. The interviews were coded using open coding for the thematic analysis. The codes were grouped into common phrases and key concepts. These were constantly compared until no new emergent themes were present indicating saturation.

Thematic analysis has been done based on the responses of the interview participants to detect the common patterns for expanding them to form an extended literature review referring to the secondary information sources. The secondary data were grouped into different themes for analysis and the establishment of an extended literature review. This was accompanied by an elaborate discussion about the themes.

The research has been conducted by following the ethical considerations and guidelines provided by the academic institution . During the research adequate ethical considerations were followed for ensuring the preservation of the anonymity of the interview participants and data security. Information was securely stored by saving the collected data in a secured cloud database along with a password-protected hard drive.

A positivism philosophy was used for this investigation for the incorporation of new ideas and facts from primary respondents. An inductive approach was used due to the absence of a hypothesis and an exploratory research design has been chosen for incorporating new information and ideas regarding the research topic. The research was conducted by following the qualitative strategy as qualitative information had been collected from an interview conducted with the managers of Tengizchevroil in Kazakhstan.

Production management is the process of applying the principles of management for the production of goods or commodities in a factory (Bento, 2018). The production of oil and gas is a highly complex procedure that involves a high level of planning and organising followed by directing and controlling the entire process of production involving types of machinery and pipelines that are of high risk and volatility.

The process of oil and gas production includes the endeavour of the companies to display initial interest followed by leasing geographical regions followed by mineral leasing, geophysical survey, drilling and production (Al-Hemoud et al., 2019). The principles of project management, delivery and production management are applied for the production of oil and natural gas to ensure high quality of production and lower the cost of operations and drilling.

Project production management facility better decision making and reduction of wastage during the extraction of oil and natural gas. The use of autonomous and semi-autonomous data analytics using sophisticated information systems powered with artificial intelligence is beneficial for providing the required intelligence to oil and gas companies for investing financial capital in the identification and extraction of mineral oil (Afrin et al., 2021).

This research is based on the topic of evaluation of the impact of project production management and advanced analytics on the oil and gas industry of Kazakhstan and improvement in the overall project delivery. The data collected in the research has been done through an open-ended interview with 8 managers of Tengizchevroil in Kazakhstan.

This chapter presents the questions asked in the interview along with the responses of the respondents. Thematic analysis has been conducted by identifying the patterns from the responses of the participants for an extended evaluation followed by the presentation of the findings and discussions.

The interview questions asked to the managers of Tengizchevroil are as follows:

In his response, the respondents said that I have been working as a project production manager in the oil and gas industry for the last 15 years.

The interviewee mentioned that he had been working as an engineer and manager with experience of more than 20 years in the oil and gas industry.

The respondents said that he has experience of 5 years in the industry.

I have been working as a production manager for more than 10 years and I specialise in the supervisor of drilling and production operations.

After being asked the question regarding experience, the respondents said that he has an experience of more than 14 years in the industry and he specialises in the development of new strategies for increasing safety and increasing production at the same time.

In his response, the manager said that the upstream activities in the oil and gas industry involving the production and exploration of petroleum and natural gas is highly challenging. Specifically, the creation of geological service and exploration activities are highly challenging along with the process of obtaining legal rights.

Health and safety concerns are the major challenges in the production of petroleum and natural gas despite being highly important for propelling modern civilization. However unplanned shutdown like lockdown in the times of the covid-19 pandemic is highly challenging as it reduces the overall throughput of production. limitations in performance is also a major challenge for oil and gas production as it minimises the life of the mature sites and makes the process more complex and costly.

At present, the most critical challenge in the oil and gas industry is the rising cost of operations. The challenge is to remain competitive in the market by lowering the cost of production and optimising the production systems and environmental utilities in the process.

The present challenge in the production of oil and gas includes the increasingly stringent standards of environmental protection and minimization of carbon emissions. The industry is a major consumer of water and energy with sleeves to the challenge of reducing the environmental footprint for avoiding and averting the negative consequences of climate change and global warming.

Resource management, inefficiencies across the supply chain and delays within the operational processes are the biggest threat in the production of oil and gas. The increasing number of market competitors and decreasing demand for energy from fossil fuels has created a major challenge for the producers. This has resulted in the requirement of optimising the entire supply chain processes and automating the process of drilling for enhancing human safety and well-being along with improving the yield in a given time.

Efficiency in production management enhances the project delivery and refining efficiency as well as the time within the oil and gas industry. This is capable of providing a competitive advantage to the company and improving the overall quality of the product.

The efficiency of production reduces waste and diminishes the time of delivery and supply of petroleum and natural gas throughout the supply chain for refining and sending it to the customers. The operation cost also decreases due to high efficiency in production.

The efficiency of production management enables the organisational leaders and operations managers to make better decisions regarding the exploration of new sites for drilling and forecasting the product volumes. This also creates the opportunity for the operations managers to implement new strategies for improving worker health and safety.

The overall operations and supply chain operate smoothly if the production management remains efficient leading to an overall increase in profitability and gaining a competitive advantage among the market competitors.

The ability to achieve high efficiency during production in the oil and gas industry is crucial for the production of waste and optimum utilisation of the resources across the organisation and the supply chain. This reduces the time to refine the crude oil along with freeing the resources and pieces of machinery for further operations in a short span of time resulting in increased production and competitive advantage.

In his response, the manager said that my team uses advanced analytics for evaluating the seismic and microscopic data. Data analytics is used for enhancement of the characterization in the simulation of the reserves for reducing the time required for drilling and increasing the safety of operations. Analytics is important for utilising essential data and information for the enhancement of the overall performance of production firms that are used and the asset management of the petrochemicals.

In his answer, the respondent mentioned the use of advanced data analytics in his organisation for improving efficiencies of shipping and transportation. He also said that data analytics improves occupational safety and reduces hazards.

In his answer the manager input emphasis on the use of data analytics in his organisation for improving human safety. he said that the drilling process is very complex and involves high risk and the employees after extraction remain at a very high risk of being exposed to hazardous fumes. However, he said that his company utilizes predictive analytics for decreasing the risk of the employees as it locates new sources of oil and gas.

Big data and analytics reduce the cost of production in the oil and gas industry and comprise multiple internal and external benefits across the pipelines. Production efficiency is increased due to the use of analytics while the cost of operations is curtailed from several scenarios. The use of data analytics has increased the productivity of the organisation by 6%.

Data analytics has resulted in an optimisation of the upstream and downstream activities of the company along with improving the quality of maintenance to the predictive analytics technology. The use of predictive analytics and simulations are able to forecast the requirement and occurrences of maintenance that reduces the cost of downtime maintenance in the long term. Predictive maintenance optimises the downtime for maintenance operations across the entire supply chain and drilling sites. This also enhances the efficiency of the operations and improves the dependability of the gas compression system. AI-powered algorithms are used for forecasting the breakdown across the supply chains and operational regions with very high accuracy for enhancing the productivity of the compressor train. Precautionary maintenance strategies of the businesses are also enhanced due to data analytics that results in timely replacement and examination of equipment.

The project delivery across the organisation is executed by following the upstream, midstream and downstream activities. The use of machinery for drilling and refining the crude oil is used for timely project delivery at the organisation. However, the future decisions awaited for overcoming the present complexities include the process of digitisation and increasing the use of advanced analytics.

The organisational manager in his response said that the mechanism for project delivery in his company involves the use of a project delivery system as the processes are defined across the project that includes planning and designing of the activities and its operations. When asked about future decisions, he spoke about the complexities like delays and losses due to wastage can be overcome with the use of agile methods and advanced analytics. This will enhance the quality of the survey of the sites and increase the efficiency of the management decisions.

In his response, the manager said that the project production management system is used for project delivery for oil and gas to the customers. Regarding the future decisions in the form of digital transformation and reduction of challenges, he said that the use of autonomous technologies and advanced digital technologies like the internet of things and cloud computing can lead to automation of the production process and refining. The use of industry 4.0 technologies can also help to overcome the complexities by increasing the efficiency and throughput of production. This would include the use of disruptive innovations like augmented reality for increasing worker safety and enhancing the quality of capacity planning for calculated investments in drilling.

The respondents said that his organisation has been using the agile principles of project management along with project production management systems for project delivery and optimisation of the operational procedures involving drilling and extraction of oil and gas. He said that the future decisions are the organisation includes complete digitisation and automation in the drilling and extraction process along with the use of analytics for generating simulations and predictive data.

The manager in his response said that his company uses a centralised and decentralized environment based on the requirements of the project delivery and time. The project delivery is received based on the application of planning and forecasting mechanisms based on the input efforts and the use of resources. Capacity planning methods and supervision of the workforce are some of the methods used for project delivery at the company. The future decisions and waited at the company include complete digitisation of the operational procedures and the integration of blockchain technology for minimising delays across the supply chain and ensuring instantaneous and real-time transactions among the producers and customers. This would also reduce the depreciation of equipment and increase profits due to the elimination of delays and middlemen.

The thematic analysis has been done by identifying the common themes and patterns that are derived from the responses of the interview respondents.

The oil and gas industry are invaluable for supporting the transportation and energy industries. Despite the immense contribution and essential outputs of the oil and gas industry the sector remains less developed and lags behind in innovation compared to the other industries. This is mostly attributed to the complexities and security challenges in the industry due to dealing with hazardous and volatile substances (Deloitte, 2015).

The requirement of survey and drilling for the extraction of oil during the upstream activities are highly complex having the threat of engineers being involved in fire and leakage is one of the major challenges. The prices of oil and natural gas remain volatile resulting in uncertain demand and the emergence of low-cost alternate fuel providers.

Integrated operations have been developed in the oil and gas industry for enabling data sharing in real-time for the ease of access of multidisciplinary expertise. Also, the integrated operations processes break down the production processes in the oil and gas drilling sites and wells with parallel processes. This has led to a reduction in the cost of accommodation to some extent and the ease of movement of personnel onshore (Khalil et al., 2017).

However, there remain challenges of coordination leading to undermining performance during exploration and exploitation of the oil and natural gas. Additionally, the existing complexity persists in surveillance during oil and gas production and the uncertainties in the market.

The fixed cost-based projects in the industry pose a challenge for maintaining the projected costs as ineffective planning processed hampers the organisational readiness due to the unrealistic KPIs and inconsistent communication at the site. It remains crucial for oil and gas firms to focus on a range of human capital advisory and safety. The instance of Deepwater horizon explosion and oil spill due to the activities of BP led to the death of 11 people and injured many others apart from causing havoc to marine life and ecosystem (Joye, 2015).

Production efficiency in the oil and gas industry is determined by the total volume of hydrocarbons that are produced as an overall percentage by considering the economic maximum potential of production theoretically. An increase in the production efficiency for oil and natural gas leads to a reduction in the emissions intensity on the production facilities.

The oil and gas industry of the UK had been able to achieve an efficiency rate of production at 80% in 2020 (Oedigital, 2020). This has led to a reversal of the operational losses by 29% along with only a 1% overrun of the schedule in comparison to the planned time of delivery. this is a 14% improvement in comparison to the last two years.

Achieving the production efficiency of 80% has led to a 10% reduction in carbon emissions for a barrel of oil that is produced. Crude oil in its true form cannot be used efficiently for any functions and requires to be refined at the refinery through the process of distillation for being vaporized and broken into multiple refined components. The maximum portion of the balance is converted into petroleum and its refining efficiency remains at an average of 85% as a requires a lot of energy.

A minimum of 15% of the crude oil is lost during the conversion. In comparison, fuel oil has a higher efficiency rate of 93% in comparison to petroleum or gasoline (Nadikattu, 2020). The barrels of petroleum and fuel oil after being refined are shipped to the point of use that includes the power plants and gas stations.

Higher efficiency in the production of oil and natural gas results in an increase in the actual wellhead production. There are multiple environmental benefits associated with higher efficiency rates as less energy is lost during the conversion process and lower waste is generated.

Higher efficiency in production leads to the generation of less waste of energy due to their reduced losses of heat resulting in a cumulative reduction in the overall carbon emissions and global warming. The integration of the latest technologies like the internet of things is important for autonomous functioning of the pieces of machinery at the drilling site along with improving the methods of refining for reducing energy and heat losses during conversion for minimising environmental impact. Improving the drilling activities and utilizing the advances made in sesame can lead to better production rates through the use of hydraulic fracturing and horizontal drilling.

Innovative acquisition of data and its subsequent management can also lead to an increase in the speed of communication and improve the data mining techniques for improving production efficiency (Lytras et al. 2017). Operational safety is the process of ensuring the avoidance of unreasonable risk that can occur due to hazards as a result of functional inefficiencies.

Operational efficiency and safety are important for industrial activities for avoiding operational disturbances and minimising the impact on the intended functionality. Safety and health management of the workers are highly important in the oil and gas industry and related activities due to the harsh operational conditions along with the exposure to chemicals and the end products constituting hydrocarbons.

There are major inherent threats to the health and safety of the workers in the oil and gas industry. Big data analytics enables the maximization of the return on investment for the companies along with enhancing the safety measures for the workers. The drilling operations in the oil and gas industry have the harshest conditions that require special focus on the health and safety of the workers.

This is due to the threat of being exposed to hazardous fumes during the process of attraction that can be fatal for their health. The use of big data and predictive analytics has the potential to facilitate the autonomous location of new oil and gas sources without the requirement of dangerous drilling procedures. This enhances the health and safety e of the workers.

Capacity planning is a concept of operation management that involves the determination of the production capacity that is required for an organisation to meet the altering demands for its products in the market. Capacity planning in the oil and gas industry enables the businesses to deliver the predefined quantities of Oil and Gas to the customers by ensuring timely delivery and quality (Flichy and Baudoin, 2018).

Digital and disruptive technologies are slowly being integrated into the oil and gas industry for countering the high degree of volatility in the sector. Blockchain technology is a recent innovation that has been integrated into the oil and Gas sector for commodity tracking and trading instantaneously.

The overly complicated records along with the routine maintenance in the oil and gas industry make it vulnerable to cyber-attacks and hence blockchain technology e is used for storing the data in ledgers being inexpensive and secure. Industry 4.0 comprises technology is like the internet of things, drones and augmented reality that is also included in the oil and gas sector.

Drones are actively being used for accessing emergency situations in comparison to sending field personnel for ensuring health and safety. This also provides a higher side with visibility and facilitates inspections. Augmented reality e has become popular in the sector for reducing waste and operational expenses.

The technology improves employee safety e as it enables the instant connection with site special is and reduces the cost of travel for flying down and expert to investigate the remote facilities. Internet of things has a crucial role to play as it ensures autonomous communication among the types of machinery and equipment that leads to a reduction in the time required for manual supervision and increases the production efficiency.

From the thematic analysis, it is found that survey and drilling requirements for the extraction of oil during the upstream activities are highly complex endangering the engineers involved in harsh conditions is one of the major challenges. The fixed cost-based projects are a challenge for maintaining the projected costs as ineffective planning hampers the organisational readiness due to the unrealistic KPIs and inconsistent site communication.

Focusing on human health and safety is crucial in the sector as the consequences of the Deepwater Horizon explosion and oil spill due to the activities of BP leading to the death of 11 people and injuring many cannot be undermined. The production efficiency in the oil and gas industry is determined by the total volume of hydrocarbons produced as an overall percentage by considering the economic maximum potential of production theoretically.

Higher efficiency in oil and gas production increases the actual wellhead production. The environmental benefits associated with higher efficiency rates include lower waste and higher output. Innovative data acquisition and management leads to the increase of speed of communication and data mining techniques for improving production efficiency.

It is also found that big data and analytics enable maximization of the return on investment for the companies along with enhancing the safety measures for the workers. Blockchain technology is being integrated into the oil and Gas sector for commodity tracking and trading instantaneously. Drones are also being actively used for accessing emergency situations in comparison to sending field personnel for ensuring health and safety.

From the literature review, it is found that the operations in the oil and gas industry include the upstream and downstream production activities wherein the upstream production includes identification, extraction, and further production of raw materials. The downstream production from the oil and gas companies is mostly consumer-oriented with having ends closer to end customers.

From the interview of the managers participating in the data collection, it was found that Tengizchevroil uses a project delivery system for defining the processes across the project that like planning and designing of the activities and their operations. A project production management system is also used at the organisation for project delivery for oil and gas to the customers. From the thematic analysis, it is found that the implementation of integrated operations in the oil and gas industry for enabling data sharing in real-time for the ease of access of multidisciplinary expertise.

The integrated operation processes break down the production processes into modular stages in the oil and gas drilling sites and wells with parallel processes. These are later integrated together to allow overall quality inspection without occupying the resources for streaming the processes.

The literature review suggests that the use of data analytics in the oil and gas industry helps in the effective utilisation and implementation of resources (Flichy and Baudoin, 2018). This is achieved with better forecasts of costs and revenues for the oil and gas firms.

The incorporation of big data and unrelated data within the industry can be effectively analysed through data analytics to ascertain projections and early warning signs for important projects. Tengizchevroil has been able to better utilize gas and reduce the total volume of flaring of natural gas by 85% since 2000.

The total air emissions have also decreased by 73% per tonne by the virtue of using production management tools and technologies for project delivery (Chevron, 2021). Also, the production of annual crude oil volume for the company has increased by 159% due to the use of digital and disruptive technologies.

Project production management ensures that proper planning and strategy rising is done before initiating the drilling procedures for maximizing worker safety and increasing the efficiency and rate of production in a given time. Project delivery is improved with the use of advanced analytics and production management systems as it benefits from the predictive analytics for maintenance and assessment of drilling for maximum impact.

From the interview conducted with the participants, it is summarised that project production management is important for ensuring timely project delivery for the oil and gas companies. Big data and analytics along with the other disruptive digital technologies are important for overcoming the complexities bind using digital transformation in the sector and maximizing the health and safety of the workers. Increasing the efficiency of oil production and higher conversion rates during refining leads to the achievement of greater efficiency and reduction of waste and carbon emissions.

The current chapter deals with the overall discussion of the present research topic that has been researched and analysed with appropriate information and findings. It focuses on the conclusion that the investigation has reached after analysing past pieces of literature, which includes different opinions concerning different authors.

Moreover, the chapter concludes how the findings of this research have helped to meet the objectives of this research that specifically helped in answering the questions relating to the research topic. Therefore, conclusions have been drawn linking with the objectives of this study.

The chapter furthermore includes recommendations for this research as in what other ways the research can be conducted to help improve the quality. However, a brief about the scope for future researchers have been discussed that can help in the betterment of future investigations.

In this study, it can be concluded that with the integration of project production management and advanced analytics, the oil and gas industry has been able to reduce the operational costs that increased the expenses of the companies in earlier times. Moreover, the application of technology such as artificial technology has essentially benefited the industry thereby helping it in increasing the trading activities with the incorporation of several hedging strategies.

Upon closer analysis, it has emerged from the discussions that with the production system, the concerned industry has been able to reduce the cost and waste efficiently thereby increasing the profit generation capacity. Relating to the responses of the interviewees, it has emerged that advanced analytics has essentially supported companies within the oil and gas industry in increasing operational safety and reducing the drilling time. Therefore, it can be concluded that advanced analytics and project production systems have improved the delivery system and also increased the profitability of the companies within the discussed sector.

To analyse the processes involved in project production management in order to identify its impact on the overall operations

As per the discussion in the literature review section, it has been analysed that project production management (PPM) has been efficiently helping the oil and gas industry in delivering capital goods thereupon helping the management system relating to the operational activities.

However, it has been observed that before the PPM, the mentioned industry has been facing huge difficulty in integrating big data that is available within the industry. In this context, it came within the purview that the knowledge-management system has essentially helped the industry in understanding the potential technologies that can be used to improve the operational activities and increase efficiency rate. Moreover, this has also helped the oil and gas sector in implementing the identified technologies that helped in managing the big data available.

On the other hand, it has arisen from the responses of the participants of the conducted interview that the production management has also helped the operational managers in understanding the flaws included in the activities. Furthermore, it also helped the managers in taking up proper decisions relating to the production.

In addition, it also assisted the operational managers in making better decisions thereby helping in conducting proper forecasts relating to product volume demand in future years. The PPM framework has also helped companies in reforming the strategies that help in the reduction of cost and increase the employment percentage depicting positive growth.

Data analytics essentially helps project managers in identifying the issues and risks that are related and holds the possibility of reducing the project process. In this regard, concerning the discussion from the literature review chapter, it can be stated that data analytics has essentially increased the effective use of resources that help the forecasting process relating to revenues and costs of the concerned industry.

Moreover, it has emerged from the study that with the help of data analytics, it has been possible for project managers to schedule the task, fix the budget, and strategically conduct the project process. Upon closer findings, it has been found that the “Internet of things (IoT)” has exceptionally helped the companies within this sector in gathering huge data thereby improving the power of predicting future demand in the global market.

Concerning the interview responses of the managers, it can be stated that data analytics has helped companies in various ways. The incorporation of this technology has increased human safety, upstream and downstream activities, reduced operational costs, the efficiency of transportation and shipping relating to product delivery to end customers, and improved the ability of companies to increase their overall performance including the production process. In addition to this, it has also helped managers in identifying potential risks and challenges thereby assisting in understanding the loopholes of existing strategies and the requirement of reforming them for better results.

To investigate the impact of project production management and advanced analytics on improving project delivery in the oil and gas industry because of the project delivery issues and complexities in the industry requiring changes and digital transformation