Disclaimer: This is not a sample of our professional work. The paper has been produced by a student. You can view samples of our work here. Opinions, suggestions, recommendations and results in this piece are those of the author and should not be taken as our company views.

Type of Academic Paper – Dissertation Proposal

Academic Subject – Engineering

Word Count – 1613 words

Technological advancements and increased interest in protecting the environment promote the need to advance and upgrade inventions to meet the current age challenges. Automobiles have revolutionized humans’ mobility since the introduction of Benz’s four-stroke engine design powered by internal combustion engines (Davies 2012). Innovative car concepts are increasingly needed to solve the international conflict of public and private mobility while increasing environmental efficiency and decreasing critical carbon dioxide emissions. Customer demand for automobiles has changed to high performance, size, extra comfort that enhances the weight spiral, which has caused automobile companies to respond by producing electric car concepts (Davies 2012). These new electrical cars have caused a shift towards lightweight design to increase public awareness of fuel consumption and stricter legislative regulations on carbon dioxide emissions in the UK and worldwide. Experts have found that 100 kg saved on the mass of cars results in the 9 grams of reduction in CO2 per kilometre (Thiruvengadam et al. 2016). Therefore, reducing vehicle mass is considered imperative in terms of them being the most effective means of reducing CO2 emissions while also maintaining performance, driving quality, and safety.

It is the selection of materials that ultimately influence an automobile’s design, resulting in its price and impact on the environment. Car companies worldwide are looking for ways to make the product more affordable, while factors such as oil dependence, stricter environmental laws, and GHG emissions restrictions fuel the need for alternative power systems in cars. According to Ribeiro et al. (2007), global energy consumption can be reduced significantly if cars are made lighter in weight at least an average of 500 kg can be achieved. Studies have found other alternative materials that can replace steel bodies, such as duralumin, fibreglass, carbon fibre, and carbon nanotubes. The current study looks to analyze three such materials as potential replacements for steel in commercial vehicle chassis. The chassis plays a crucial role in developing car production as it holds the importance of housing the engine and the drive train.

The study’s primary research question is;

What will material for a chassis frame for an automobile be the most cost-effective and environmentally friendly without compromising quality?

There is an array of innovative materials available for which the study use. Metals such as aluminium are already being used as an alternative to steel in automobiles. Recent research is looking towards magnesium, carbon fibre, and fibreglass as an alternative materials. To narrow the study’s scope, research will be conducted on implementing magnesium, fibreglass, and carbon fibre as an innovative material to build car chassis using a lifecycle assessment model.

The following are the aims and objectives of the study.

Investigate three innovative materials for the design of an automobile chassis.

To achieve the study’s aims, it is essential to develop a set of objectives that will guide the research while also ensuring that the research does not result in scope creep. The following are objectives of the current study;

Orders completed by our expert writers are

The literature review indicates that there is a need for more research into selecting and selecting innovative materials for chassis. Based on the literature review, key factors were highlighted on the impact they have on selecting material for an automotive component. There is a need to examine these factors as there seem to be no relevant studies that particularly look at these factors related to magnesium, carbon fibre, and fibreglass as material alternatives for chassis.

The approach for assessing these materials in light of the following characteristics;

A material parallel to the stated characteristics previously is conducted using selection criteria outlined by Micheal F. Ashby in Materials Selection in Mechanical Design (Ashby 2011a; Ashby 2011b). The selection strategy chosen includes the following steps to determine the best innovative material for a chassis;

Based on this strategy presented by Ashby (2011), the selection procedure for finalising the innovative material for a chassis will be similar. It will contain the following steps;

Figure 2: Steps for Translation in Material Selection (Ashby 2011)

In addition to the steps of selections outlined by Ashby (2011), the life cycle analysis/assessment method will also be used to select the material based on its impact on the environment, overall cost, manufacturing/production, and longevity.

The LCA methodology is used to assess the new innovative car component materials through their respective life cycle to evaluate the corresponding environmental impact. Using this model, the research can verify if the material has a lower environmental load and in which phases it contributes the most to the global environmental impact. Davies (2012) the LCA is an imperative tool that needs to be used for guiding the environmental design improvements in the automotive industry. Raghuvanshi et al. (2015) define the LCA as a quantitative evaluation of ecological aspects, including GHG emissions, energy consumption, and acidification. The process consists of the following phases (see Fig. 3) that will be implemented in the current study;

Figure 3: LCA Model

Before the LCA is conducted, it is imperative to specify boundaries by deciding the processes that need to be examined. To evaluate the environmental aspects and potential effects linked to the chassis’ material from raw material acquisition to final product disposal, an LCA methodology based on International Organisation for Standardisation (ISO) will be used (van der Harst et al. 2014; Liamsanguan & Gheewala 2008). For this particular reason, the need for the LCA software SimaPro 8.2.0 arises. The software allows the researcher to access the problem-oriented approach CML 2 baseline 2000 to assess the material component’s environmental impact.

The purpose of the LCA under this study will be to identify options for improving the car component’s environmental performance under its more innovative material (Inaba et al. 2010). The results of the assessment can be used for product and process development by automotive companies. This will allow manufactures to analyse the impact of changes in the process, meaning the technology, inputs, and production composition as a whole on the environment (Domenech et al. 2014).

The interim report provides an overview of the research that needs to be conducted. To achieve the aims and objectives outlined, it is essential to provide a detailed plan of work. The methodological approach provides insight into the steps that will be taken to conduct the research.

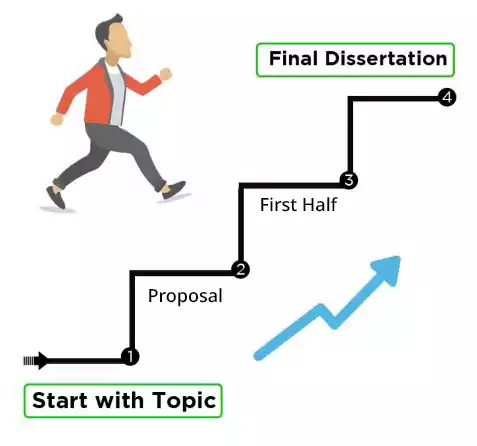

The plan of work for the current research includes the following;

Although the research being conducted does not develop equipment, nor does it hire burdensome mechanical equipment, it does need crucial software for its analysis. This research’s crucial software is SimaPro 8.2.0, which will be used for the life cycle analysis. Unfortunately, the system is on a subscription basis that is customised, and a concrete quote is available. A quote has been put to the company. However, it would be required by the educational institution to provide the software for research.

If you are the original writer of this essay and no longer wish to have the essay published on the www.ResearchProspect.com then please:

To write an undergraduate dissertation proposal: